Theme I: Smart Materials-based Nanostructure for Sensors (smart-skins)

Our group introduces new electroactive materials from the nanostructure level in the development of smart materials-based e-skins. In our research, the processed active materials and composites, such as conductive polymers 1D and 2D materials, for uses in energy and biomedical applications such as flexible transducers are investigated. This led to the design and development of novel flexible electronic sensors. In addition, our group has demonstrated new smart materials systems using conductive polymers and 1D and 2D nanomaterials for actuator systems. They have applied conductive polymers with novel architectures as electrodes for self-powered sensors. It has also been applied to devices such as flexible electronics and wearables. We design and develop novel flexible electronic sensors of significance.

Theme II: Smart Materials and Auxetics 3D and 4D Printing for Soft Robotics

Our group developes new shape memory blends and their composites, mainly thermoplastics materials 1D and 2D materials. We studied the blending and interfaces of these polymers and their effect on the shape memory phenomenon and demonstrated that these shape memory systems and composites can be used as high-performance actuators and artificial muscles. Naguib has developed for the first time an active pore structure as a dynamic absorbable system using shape memory materials. The group has also developed an active metamaterial as origami (folding structure systems), based on Miuri origami, made of shape memory blends. We designed and developed 3D materials systems for high-impact and anti-ballistic materials for body armour. In addition, our research resulted in the development of a new class of miniaturized soft robots that can be utilized as synthetic organs and limbs, drug delivery systems, and active wearables in smart textiles.

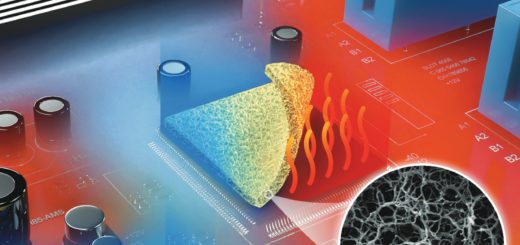

Theme III: Energy and Thermal Management Materials and Aerogels

Our group develops novel synthesis technology for the production of conductive composites and substrates for energy harvesting and storage. The resulting new materials have been applied in triboelectric nanogenerators. This has led to the development of new disruptive technology for a new class of aerogels-based energy harvesters with high performance. We have also applied conductive polymers with novel architectures as electrodes for coin batteries and supercapacitors. Increasing demand for technology for novel metamaterials with unique properties such as high service temperature, super insulation and ultra-lightweight flexible structure motivated the development of new porous materials to be used for thermal management and insulation in many fields such as aerospace, electronics, electrical vehicles, and transportation. In this context we developed new aerogels with superb thermal management properties are present very high potential to be developed as the next generation of novel thermal materials.

Theme IV: New Biomaterials Systems for Medical tools and Bio-electrodes

Our group has also been working in collaboration with the Sick Kids Hospital to produce medical tools and sensing systems for minimally invasive surgeries. We have designed and developed for the first time new sensing systems on medical tools. This research has resulted in enhancement in the medical tools designed and the feedback signals associated with it, which led to better procedures and more control of the forces. The work has been extended to develop new medical imaging phantoms for the liver and brain to test these systems. Electrical stimulation of the brain through the implantation of electrodes is an effective treatment for neurodegenerative diseases and the focus of a large body of research investigating new cell mechanisms, neurological phenomena, and treatments. Our group utilizes 3D printing to produce an effective 2-channel stimulation device that meets these requirements. 3D printing minimizes the amount of material used in manufacturing the device.

Theme IV: Low Carbon Footprint Materials and Composites Under Extreme Conditions

Our group designs and develops new biopolymer and composite systems, producing new materials made of bio-based and recyclable blends. We have also investigated the mechanical properties of fibres such as carbon glass, and bio-based composites such as lignin and tannin. We also investigate the aging properties and transport phenomenon including gas and permeation, dynamic properties and creep of new composites systems. The processing technology and material developed as a result of this research serve the energy, packaging and transportation industries in the application of low-carbon footprint products with enhanced mechanical and damping properties. Our group developed new hierarchical composites with tailored surface properties by designing micro- and nano-3D morphologies and optimizing processing and material parameters. Our research is leading the way in transforming solid polymers and gels, into textiles for wearables.